In forklift operations, blind spots are one of the main causes of accidents. There are a large number of forklift accidents each year where blind spot issues are a major contributing factor to impaired operator vision. Data from the U.S. Bureau of Labor Statistics shows that between 2011 and 2017, more than 7,000 people per year were seriously injured in forklift accidents that resulted in long-term incapacitation.

Table of Contents

Challenges Posed by Blind Spots

Forklift industrial accidents primarily involve forklifts colliding with people or other objects. Drivers need to pay attention to several factors at once, such as cargo, height, and turning, during operation, which increases the risk of accidents. Blind spots are particularly problematic, especially when cargo is being loaded and the front is completely obscured, creating a blind spot in the line of sight.

1.1 Cargo Obscuring Vision

Cargo is loaded in such a way that the driver’s forward vision is completely obscured, increasing the likelihood of a collision. Even without a load, the structural elements of the forklift limit the operator’s ability to clearly see his surroundings.

1.2 Blind Spots Around The Forklift

Structural elements such as bulkheads, fork carriers, attachments, etc. can be a source of blind spots, preventing the operator from having a clear view of the area in front of the forklift. This further increases the risk of collisions in busy environments.

The solution: the use of camera technology

To address forklift blind spots, camera technology has emerged as an effective solution. Here are some key ways to tackle the blind spot challenge:

2.1 Cargo Obscuring The Line Of Sight

Installing a HD camera system on a forklift truck, especially on the fork arms, allows the driver to observe the ground directly in front of the truck, even if there is cargo loaded. This improves the driver’s field of vision and helps prevent accidents caused by cargo obstruction.

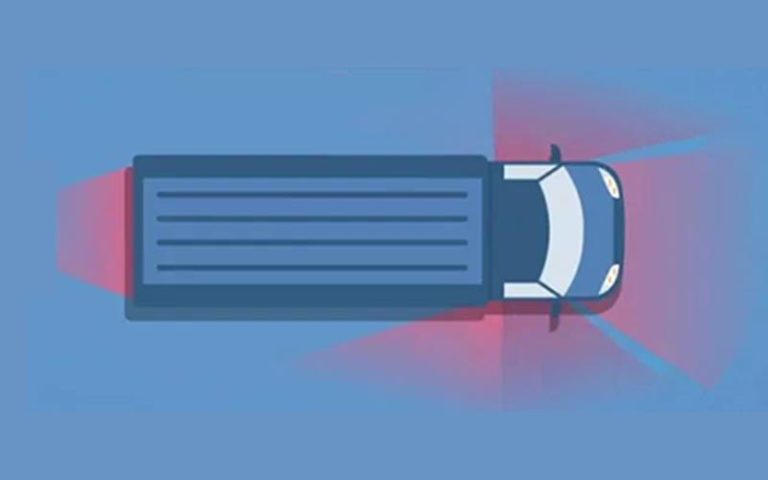

2.2 Blind Spots Around Forklift Trucks

Camera systems can be installed not only in front of the forklift, but also to cover the blind spot areas around the forklift. By installing a digital reversing camera and a front view camera, the driver can have a clear view of the environment around the forklift truck, minimising the risk of collision.

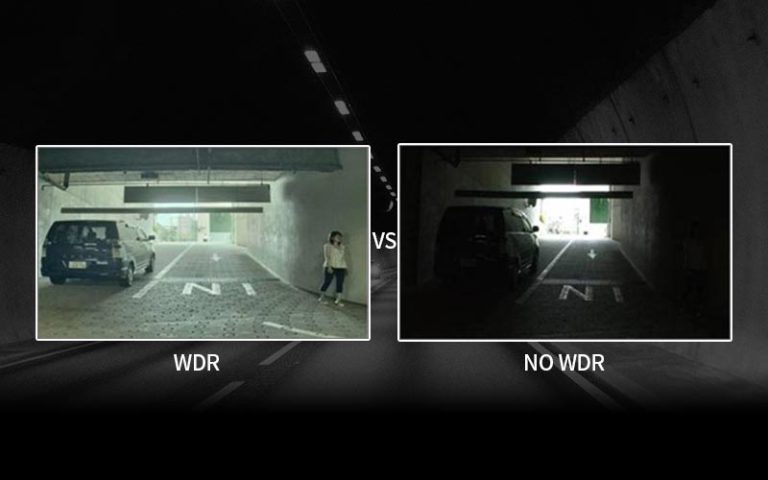

2.3 High Resolution Digital Camera

The use of high resolution digital camera systems, such as the AHD rear view system, provides high definition images without delay, allowing the driver to better observe the work area around the forklift and ensuring greater safety when reversing.

Through the application of these solutions, we can better address the challenges posed by forklift blind spots, improve the safety of forklift operations and reduce the number of accidents.